Project Requirements

The catapult project is a project assigned every year at my school for AP Physics I students. The objective is to design and build a catapult which can consistently launch a small square bean bag into a minertaure cornhole as distance of two science desks, or about three meters. There is a $50 dollar budget for the catapult and every item used must be factored into the total cost including those which the builder already owned. At the end of the project all catapults compete in a bracket style tournament to determine the winner. Spolier… we won.

Key Design Goals

-

High precison and repeatability

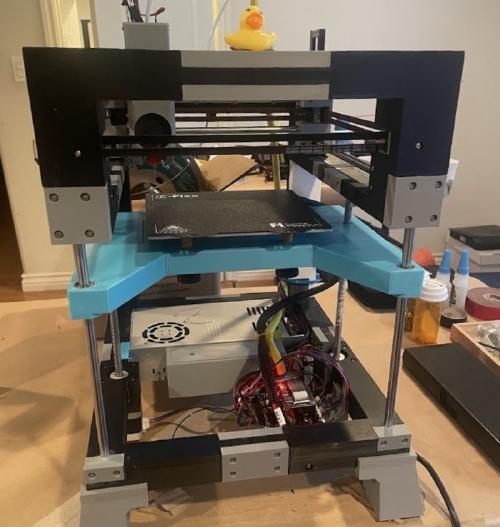

- Main axle rides on bearings and the whole strucutre is as rigid as possible

-

Adjustable power needed during competition

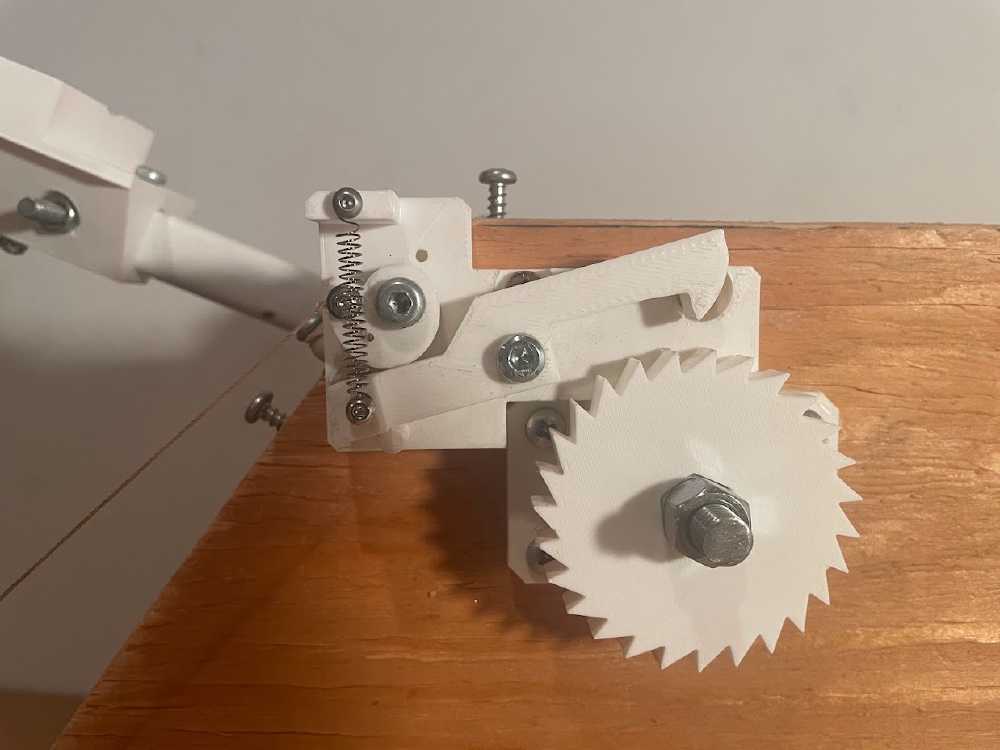

- Acomplished with rubber band tension adjustment and wracket style trigger system.

Main Features

- Wratchet trigger system allows for adjustable power, repeatability, and triggering from a distance.

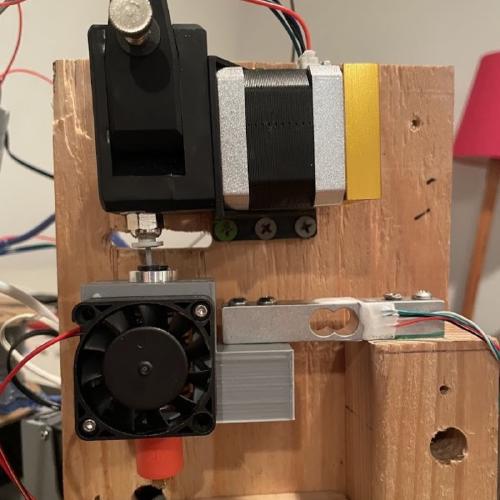

- Rubber tube pulleys cater to the nature of the rubber tube we bought which provided the best force when stretched over a large distance with moderate force.

- Rigid axel on bearings allows for minimal side to side inconsistancies when launching.

Problems and Solutions

When testing the catapult had remarkable precision regarding the distance the bean bag would reach. However shots were often inconsistent side to side, which some landing perfectly on the target and others way off to the right. After inspecting the catapult in slo-motion video, I decided that the error could not lie with the main launching mechnism. The trigger was very consitent shown by the distance precison, and the bearings and main alminum shafter were almost impossible to wiggle side to side by hand. Thus the only component left was the beanbag compartment. I experimented with different designs, and concluded that the way the beans were dispersed within the compartment before each shot was critical. If more beans were off to one side the bag might look centered, but its displaced center of mass would cause it to be flung off to the side missing the target.

The final solution was a smaller bean bag compartment with no chanfers on any of the edges. The bean bag would be folded into the smallest size possible where the beans had little room to move. Then the bag could be stuffed into the compartment. This solution provided far better accuracy and enough for us to sweep the competiton come tournament day. Addtionally I desgined a compartment which as the size of the bean bag unfolded, and which would have a stamp which would press the beans flat and uniformly each time. However this desgin was never tested, and I suspect improvements would be minor compared to the folding meathod.

Overall this project consisted of alot of itterations of parts as seem below.