Previous Set-up / Issue

Before the boxes were modified, tape handles were added to some boxes to make them easier to pull out from the shelf. However, this solution proved inadequate. Some boxes are also hefty, making them more difficult to manipulate prior to these alterations. The corrugated bottoms of the boxes caught on the rim of the bakers rack, making them more difficult to slide off the shelf.

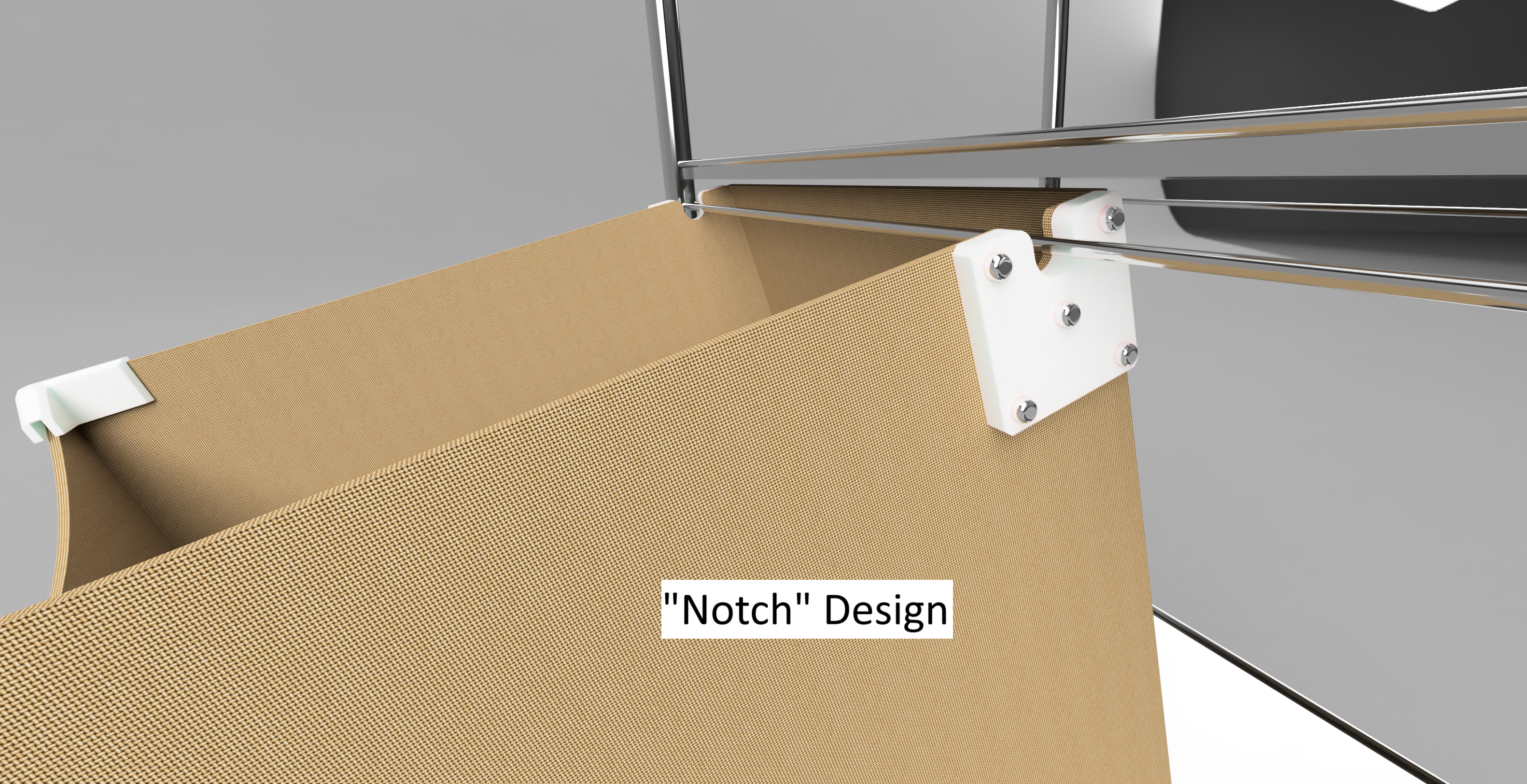

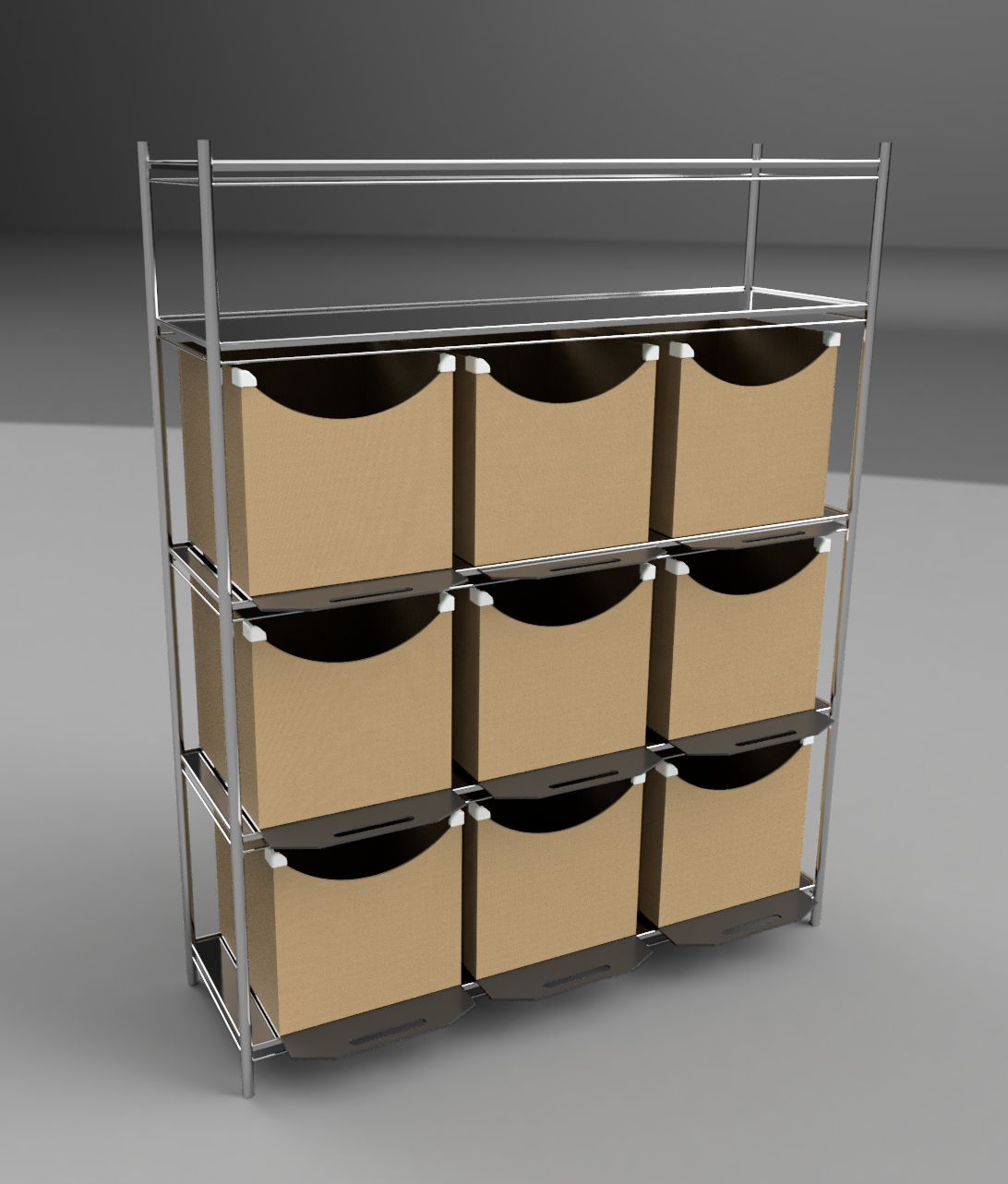

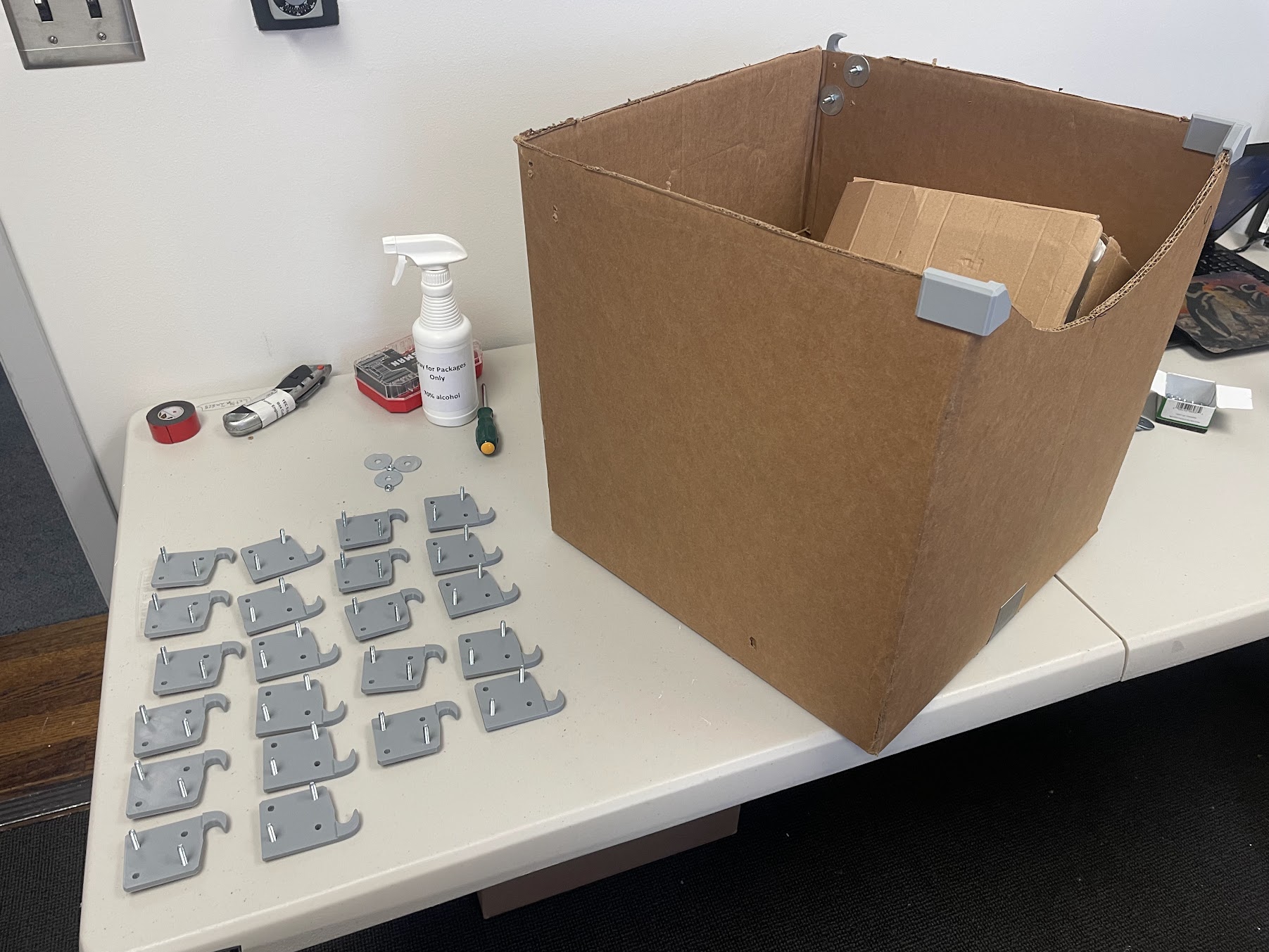

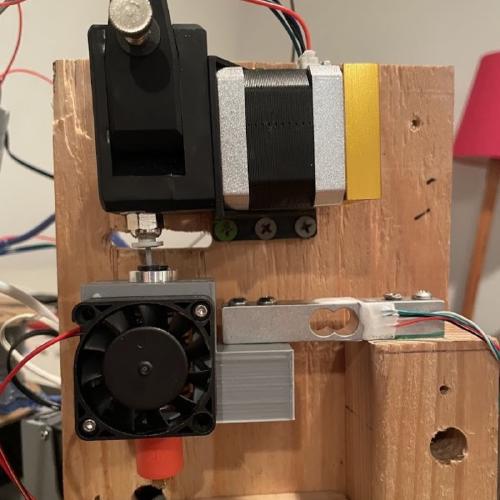

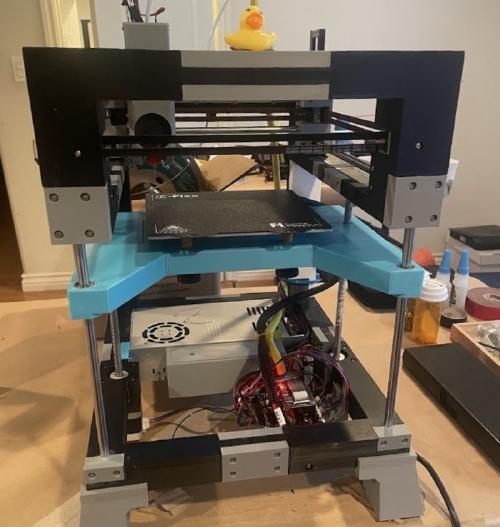

In this design, we glued HDPE sheets with cutout handles underneath the boxes, which slide right over the rim of the bakers rack. Additional parts are 3D printed, such as the corner guards as well as the hooks, that hold the box leaning open on the edge of the shelf.

Box Modification Idea

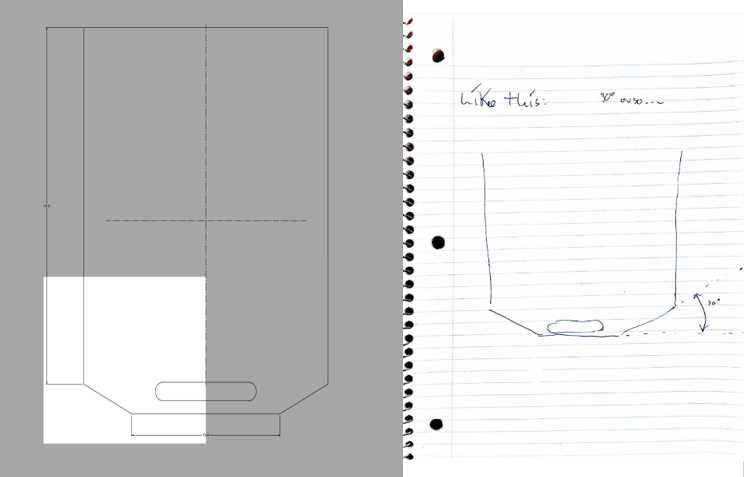

Below is the stencil for cutting the handle shape in the HDPE plastic sheet. This stencil is generated from the Fusion 360 CAD model by projecting the HDPE sheet model onto an 8.5x11” canvas. Then it is printed on two sheets at a 1:1 scale. My supervisor and test manager at Tenco recommended we add 30-degree relief cuts to the corners. He sent me a quick drawing a few minutes later, from which I could quickly update the CAD model to match.

The Idea in CAD

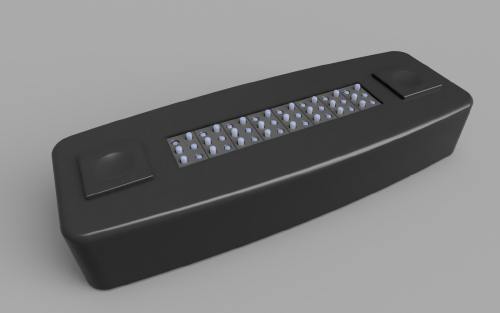

Below shows a render and a finalized box. White corner guards protect the corners of the cut cardboard from having their corrugations damaged after repeated use. The black HDPE sheet has a slot cutout to serve as a handle to slide the box out from the shelf.

Different hook ideas were disscussed, the final product ended up evolving into a mix between the two.

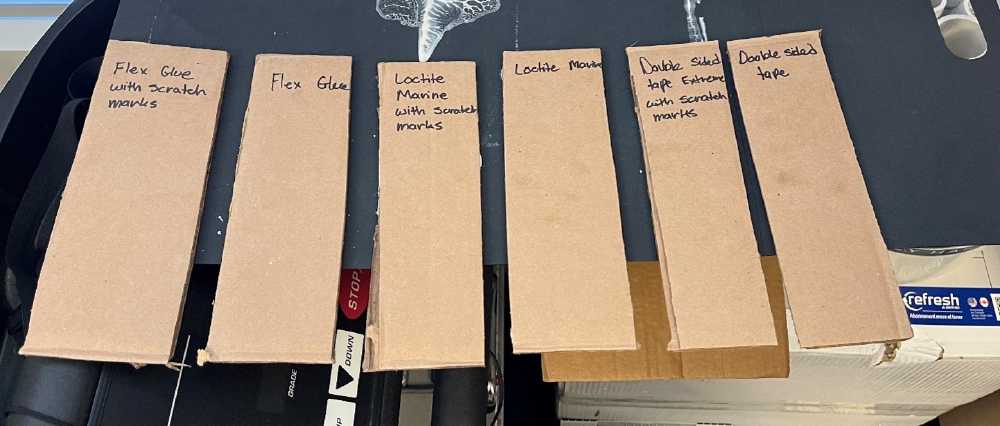

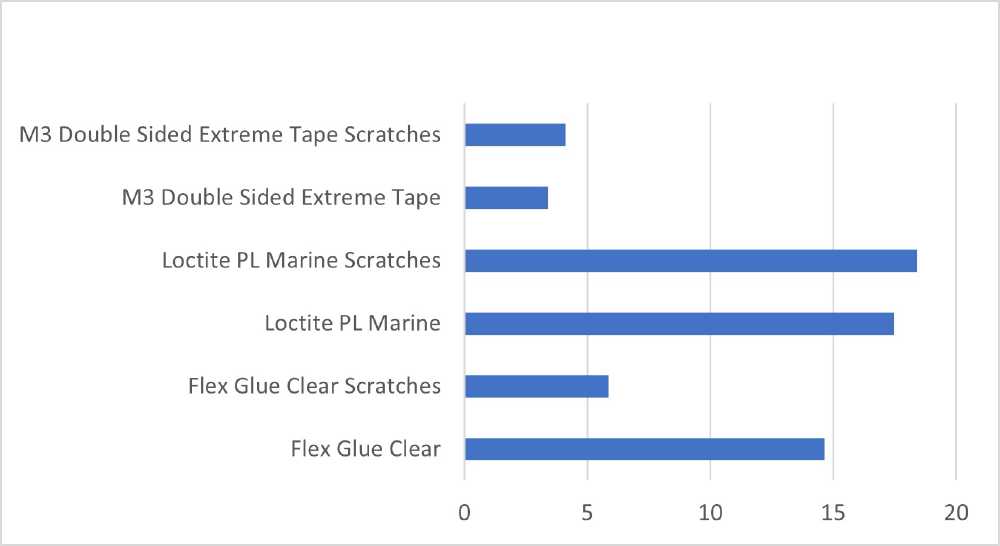

Adhesive Testing

An adhesive would be used to fasten the HDPE sheets to the bottom of the boxes. Multiple glue brands along with double sided tape were tested, to find which was the strongest for this application. These included, Flex Glue Clear, Loctite PL Marine, and 3M Extreme Double Sided Tape. Each adhesive was tested with the HDPE sheet bare, and with scratch marks to increase the surface area for the adhesive to grip to from the box knife to test its effects on adhesion.

Final Design

These modified boxes allow the contents of the box to be seen easily without a heavy box needing to be taken off the shelf and placed on the floor. Additionally, boxes can stay propped open, making the stowing of objects to multiple destinations easier and more efficient.